Advantages of Automatic balance valve in the Chiller system

03/10/2019

As one of the systems that are widely applied in many areas of daily life, the Chiller central air-conditioning system plays the role of producing cold water, providing cold water for concrete, cooling the plants and chemical mixing stages, ... Chiller central air conditioning system works well or not depends on the balancing systems.

Along with the development of technology, the balancing system has been increasingly improved, meeting the increasing requirements of the process of designing, installing and operating Chiller. The following article will highlight the advantages of automatic balancing valves in the Chiller system.

Along with the development of technology, the balancing system has been increasingly improved, meeting the increasing requirements of the process of designing, installing and operating Chiller. The following article will highlight the advantages of automatic balancing valves in the Chiller system.

I. Why balancing system is important?

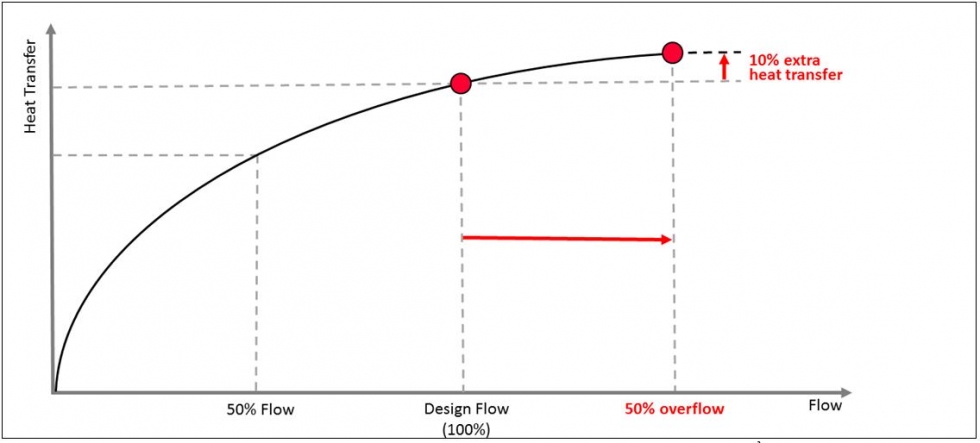

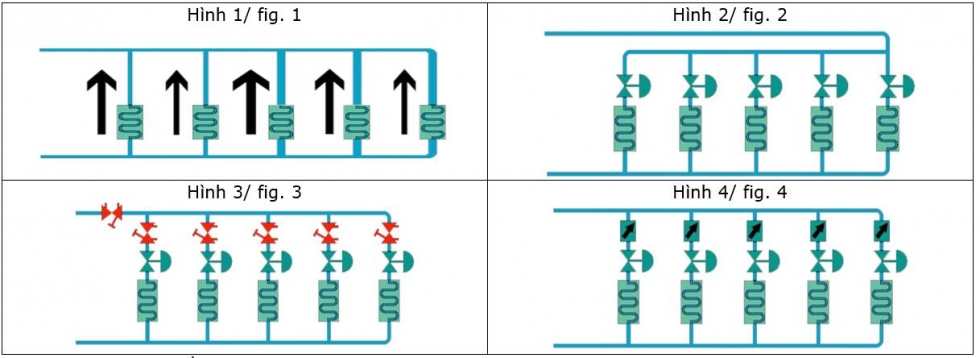

The performance of the system is assessed by the efficiency of heat transfer through the coil with the mechanism as shown below.

Figure 1

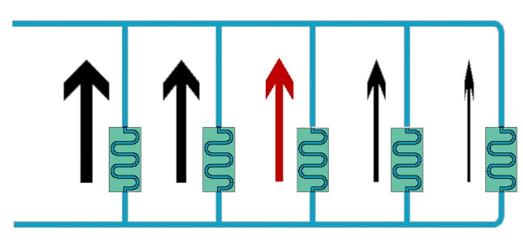

- If there is no reasonable design, the flow passing through the coil will be distributed incorrectly as required. As shown in Fig. 2, the coil near the pump has flow exceeding design, the coil far away from pump the has flow not met design.

- Thereby, balancing the flow between the coils is essential for the system to ensure the efficiency of the heat transfer will significantly save the cost of equipment, power.

Figure 2

II.The types of balancing valve

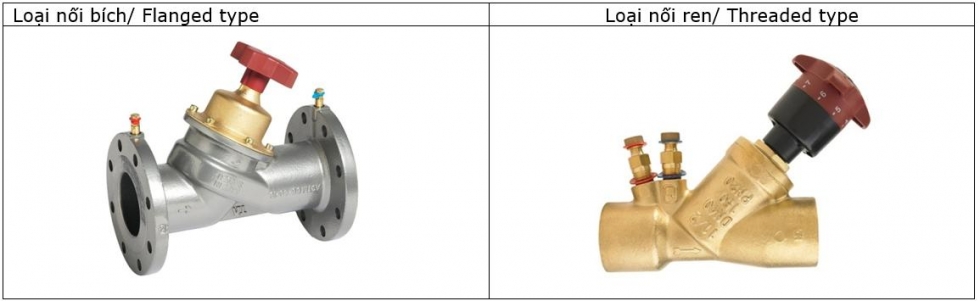

- Static (or manual) balancing valve

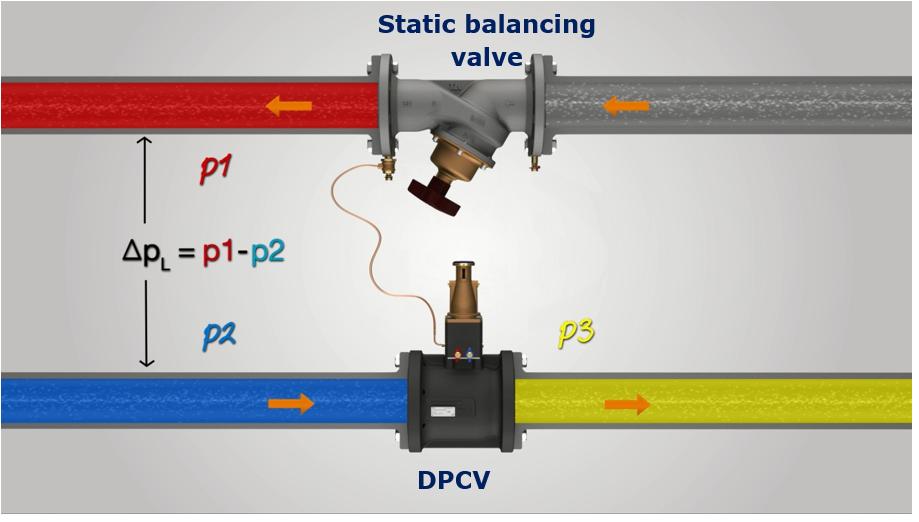

Static balancing valves only maintain constant flow when the pressure difference before and after the valve is constant. Therefore, to ensure constant flow, a static balance valve should be installed in combination with the DPCV pressure differential control valve as shown below.

- Dynamic balancing valve

Dynamic balancing valve, also known as automatic balancing valve: this valve replaces the role of the static balance valve and the pressure difference control valve. The valve flow is always maintained with a constant band in the range of P. If smaller or greater than the P range, the valve flow will change.

- PICV

.jpg)

.png)

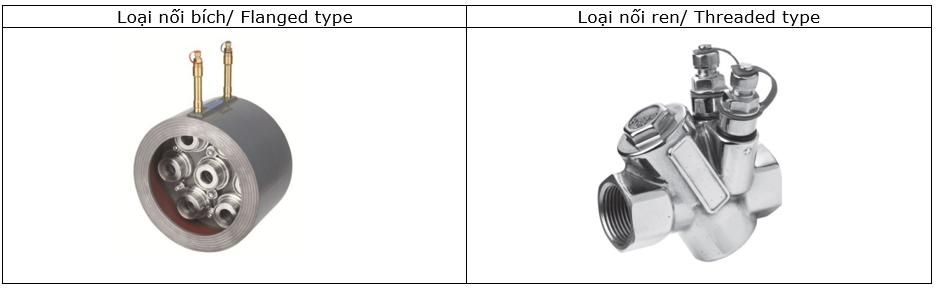

PICV is a pressure independent balancing valve with motor control on / off or modulating. The valve can replace functions of 3 types of manual valve / DRV + differential pressure control valve / DPCV + control valve

IV.Balance methods, pros & cons of balance methods

Currently balancing methods in Figures 1 and 2 have no longer been used because of the difficulty and complexity in system calculating.

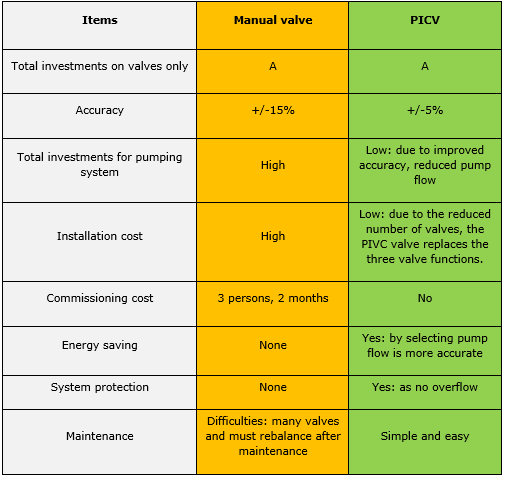

Nowadays, Chiller systems often use the method of using static balancing valves in Figure 3 and using automatic balancing valves in Figure 4. The advantages and disadvantages of these two methods are shown in the table below:

Nowadays, Chiller systems often use the method of using static balancing valves in Figure 3 and using automatic balancing valves in Figure 4. The advantages and disadvantages of these two methods are shown in the table below:

V. Some notes when selecting automatic balancing valve PICV

- Q (l / s) / required the flow of the equipment (FCU, AHU...): Because the PIVC valve is designed with control of constant flow through the valve when difference pressure changes within a conventional range. Selecting the valve have to ensure the amount corresponding to the maximum flow required through the equipment to ensure the refrigeration capacity of the equipment

- Max close off pressure/ maximum pressure the valve can close, greater than this pressure the valve will close not closed: PIVC valve has an integrated electric motor so the valve should be selected to the closed pressure index of the valve because in the chiller system when operating, there is always a difference between the supply and return lines (pressure before and after the valve) and the branches near the pump are usually the ones with the largest pressure difference (In this regard, it should be noted for the case of selecting the other valve integrated electric motor)

Other articles

- Sigma launched the awareness training program on ISO 9001:2015, 45001:2018 & 14001:2015 (02/03/2023)

- Sigma implements the ISO 45001:2018 management system audit and monitoring program (20/10/2022)

- Sweating on HVAC system during operation (28/09/2020)

- Why is Ventilation so Important for Buildings? (19/08/2020)

- Effects of harmonics caused by VFD of the HVAC loads in the modern power systems (06/05/2020)

- Some notes in the desgin of the domestic hot water system (19/09/2019)

- Sigma maintaining the quality assurance work at the project (03/09/2019)

- The activities of internal quality management at the project (12/01/2017)

- ISO 9001:2015 Certificate

- Project Total Internal Audit Program at Sigma (23/09/2016)

Partners

_thumbcr_130x97.png)

Address :

Address :  Email :

Email :  Tel : (84-24) 3 9288683 | (84-24) 3 9289235

Tel : (84-24) 3 9288683 | (84-24) 3 9289235 Fax : (84-24) 3 9288667

Fax : (84-24) 3 9288667.png)