Sweating on HVAC system during operation

28/09/2020

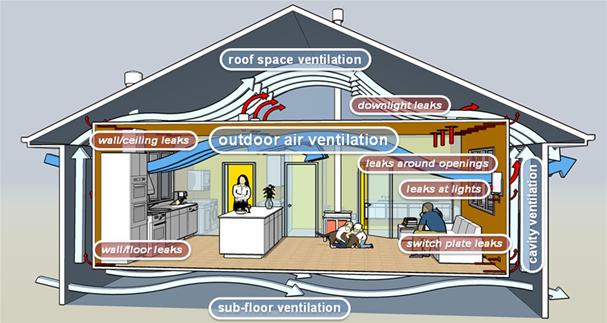

Most projects have dew condensation in HVAC systems. The problem of inlet dew occurs in the slit air inlets and in the air inlets installed in common spaces. How to fix this problem?

I. Why sweating is a problem of the HVAC system?

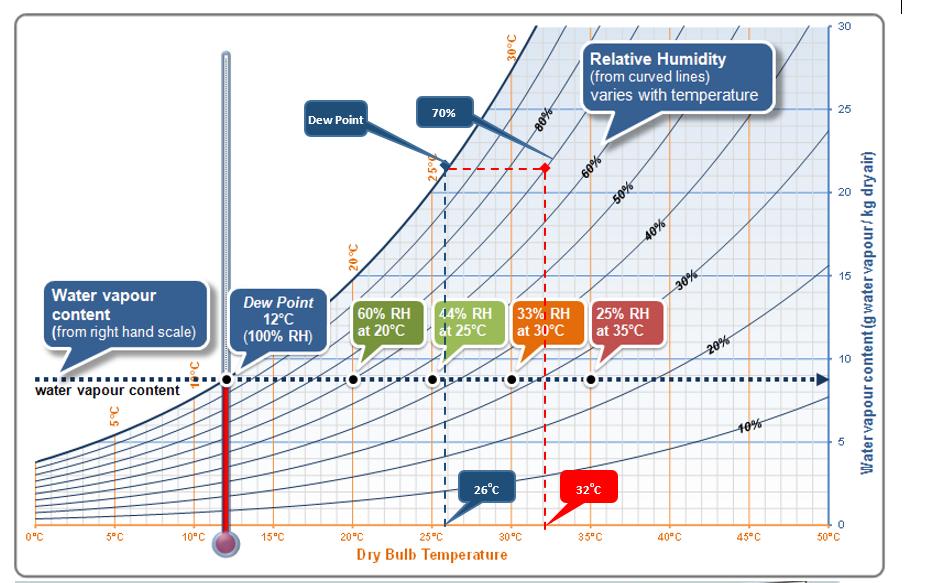

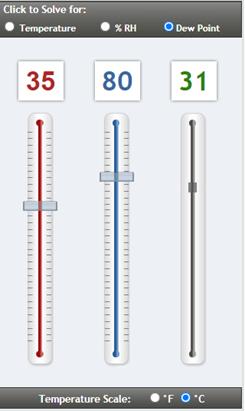

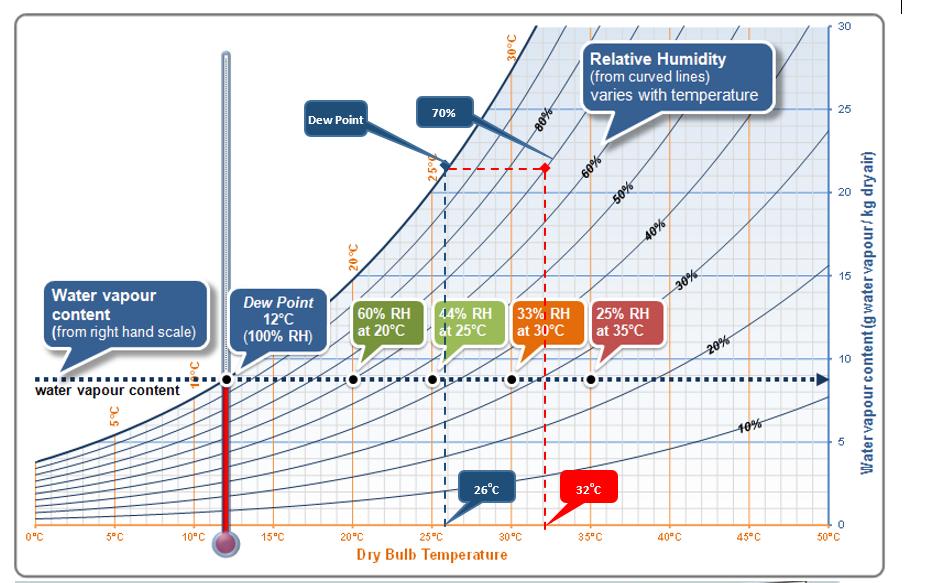

1. The lower the temperature, the higher the relative humidity (RH), or in other words, the hot air can hold more steam than cold air

2. When the RH reaches 100%, the accumulated water vapor has reached a state of “saturation” or dew point

3. The more humidity in the air (absolute humidity), the higher the dew point temperature

III. When/ Where does sweating occur inside the building?

III. When/ Where does sweating occur inside the building?

1. The AC system runs for the first time; the sweating often occur due to the air inside the building is very warm and moist

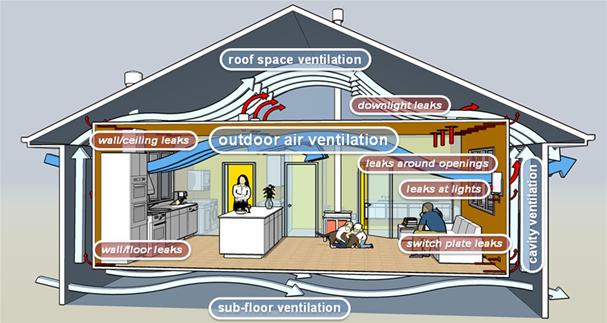

2. Outside air movement through the indoor at the location having a high level of humidity such as north area, beach coast area and islands or weather change immediately from cold to warm

Sweating happens when insulation work not done properly/ leak thus the temperature of the insulation’s surface is below the dew point temperature of surrounding warm, moist air

Sweating happens when insulation work not done properly/ leak thus the temperature of the insulation’s surface is below the dew point temperature of surrounding warm, moist air

Sweating insulation surface of the chiller pipe Sweating insulation surface of the condensate pan

.png)

.png)

Address the Issue:

A dirty filter, dirty heat exchangers, high resistance of duct line, static head of AHU, FCU, PAU is low, the motor valve on supply chiller water pipe to FCU, AHU, PAU cannot close, leading to surface temperature of equipment is lower than the dew point of the surrounding air, causing sweating/ condensation

Address the Issue:

The dew point should be determined specifically for the most extreme weather of the year, then calculate to select cold capacity, insulation thickness that best suits the characteristics of weather and usage to avoid sweating/ condensation which is one of the major problems that causes unpleasant / undesirable damage during HVAC system operation.

Vietnam is a country with a hot and humid climate, although it depends on the region and the time in which the temperature and humidity change. In the process of designing, the specific climate of the construction area should be carefully examined and evaluated. The charts below show the differences in weather factors between regions and months of the year in our country.

Sweating is a symptom of a larger problem with the HVAC system. Dripping moisture is an unpleasant occurrence. Over time, the accumulation of moisture will contribute to the rusting of the diffuser and damage to the surrounding ceiling system, the equipment & furniture under the diffuser

II. Mechanism of Sweating1. The lower the temperature, the higher the relative humidity (RH), or in other words, the hot air can hold more steam than cold air

2. When the RH reaches 100%, the accumulated water vapor has reached a state of “saturation” or dew point

3. The more humidity in the air (absolute humidity), the higher the dew point temperature

1. The AC system runs for the first time; the sweating often occur due to the air inside the building is very warm and moist

2. Outside air movement through the indoor at the location having a high level of humidity such as north area, beach coast area and islands or weather change immediately from cold to warm

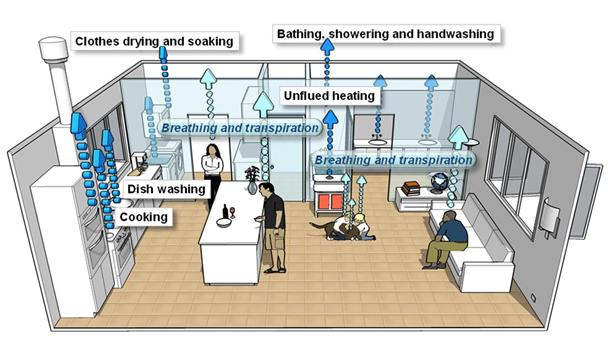

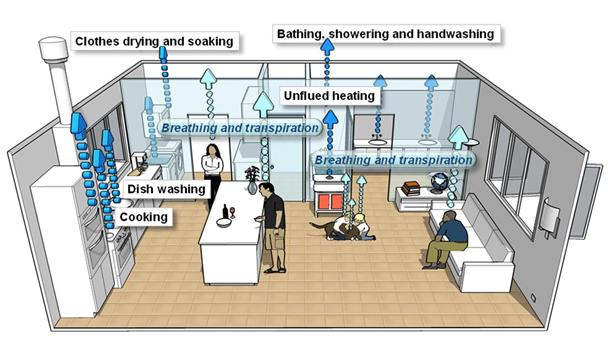

3. A place where a lot of moisture is generated due to activities from inside such as restaurants

4. Smooth surface made from steel/ glasses

5. Where there are pipes, air-conditioning equipment passing (cold water pipes, gas pipes, supply ducts, diffuser...) the construction, installation or use of materials, operation and maintenance do not comply with requirements.

IV. Sweating on the air conditioning system and remedial measures

1. Sweating supply-air diffuser face

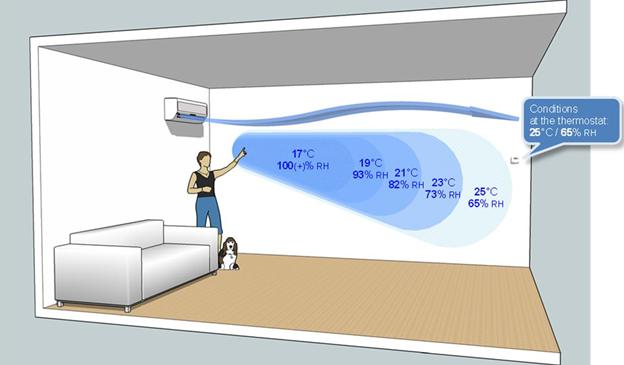

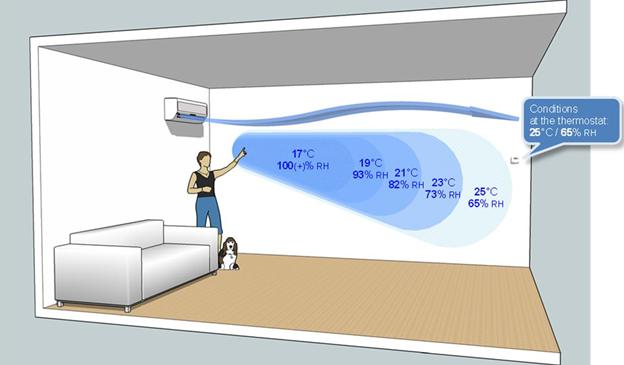

Sweating occurs when the warm, moist room air contacts the diffuser face while the supply air temperature is below the dew point temperature

5. Where there are pipes, air-conditioning equipment passing (cold water pipes, gas pipes, supply ducts, diffuser...) the construction, installation or use of materials, operation and maintenance do not comply with requirements.

IV. Sweating on the air conditioning system and remedial measures

1. Sweating supply-air diffuser face

Sweating occurs when the warm, moist room air contacts the diffuser face while the supply air temperature is below the dew point temperature

- Decreasing the difference between the room temperature and the supply air temperature (ΔT) by adjusting the thermostat to a higher temperature and increase to the CFM into the occupied space to ensure the space’s load requirements (if the designed load is low, this method cannot apply).

- Seal the gap of the air-box and air diffuser's neck by insulation to prevent cold air entering to the gap to reduce the temperature of air diffuser's face

- Insulation blanket on the backside of the diffuser

- Using plastic diffuser instead of metal diffuser

- Keeping the humid air outside by minimizing open doors and windows

- Not arrange the supply air diffuser next to door, curtain wall directly contact to outdoor

Sweating insulation surface of the chiller pipe Sweating insulation surface of the condensate pan

.png)

.png)

Address the Issue:

- Use enough thickness insulation and note to choose the suitable insulation for the climatic conditions of each applicable region

Sweating happens when the duct goes through the cool/ cold area such as an open ceiling or ceiling air return which is not insulated properly thus it made temperature inner duct's surface below the dew point of warm, moist air contained inside

Address the Issue:

- Insulating for the duct such as out air duct, exhaust air duct…etc. which go through the cool/ cold area

- Installation of Non-Return damper for exhaust duct to prevent penetration of out-air

A dirty filter, dirty heat exchangers, high resistance of duct line, static head of AHU, FCU, PAU is low, the motor valve on supply chiller water pipe to FCU, AHU, PAU cannot close, leading to surface temperature of equipment is lower than the dew point of the surrounding air, causing sweating/ condensation

Address the Issue:

- Periodically clean the filter and coil

- Choosing the static pressure head of FCU, PAU, AHU to overcome the resistance of the duct-line and ensure the air speed at the supply-air diffuser from 2-2.5m/s

- Designing duct-line must ensure that the resistance of the duct-line is not too high

- Do not install flexible ducts that are too long, dented or folded

- Check the operation of the electric valve, note the closed pressure while selecting the electric valve

The dew point should be determined specifically for the most extreme weather of the year, then calculate to select cold capacity, insulation thickness that best suits the characteristics of weather and usage to avoid sweating/ condensation which is one of the major problems that causes unpleasant / undesirable damage during HVAC system operation.

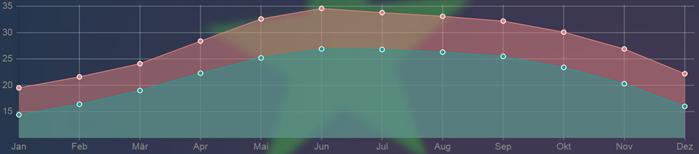

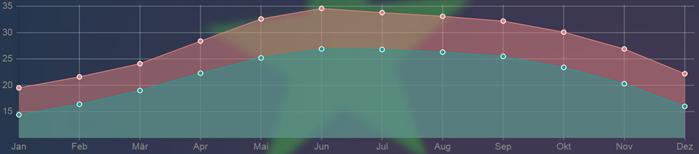

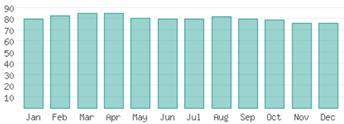

Vietnam is a country with a hot and humid climate, although it depends on the region and the time in which the temperature and humidity change. In the process of designing, the specific climate of the construction area should be carefully examined and evaluated. The charts below show the differences in weather factors between regions and months of the year in our country.

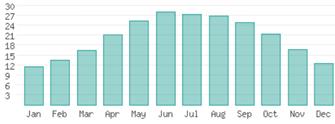

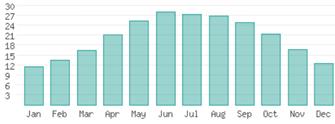

Average daytime and nighttime temperatures in Ha Noi

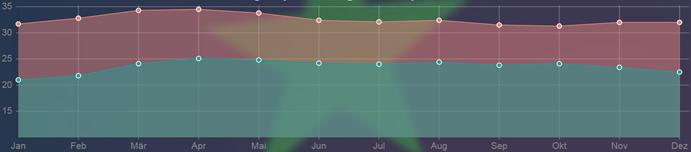

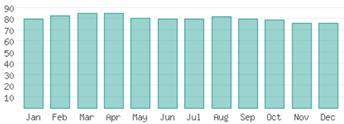

Relative humidity in % Absolute humidity in g/m³ (approx.)

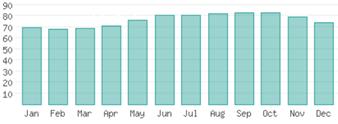

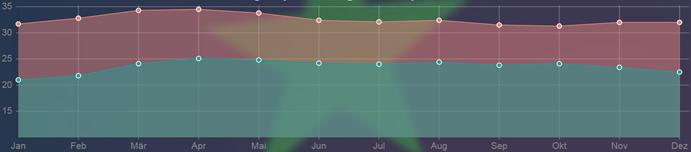

Average daytime and nighttime temperatures in Ho Chi Minh City

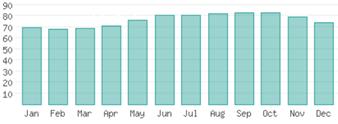

Relative humidity in % Absolute humidity in g/m³ (approx.)

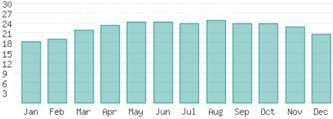

Average daytime and nighttime temperatures in Ho Chi Minh City

Relative humidity in % Absolute humidity in g/m³ (approx.)

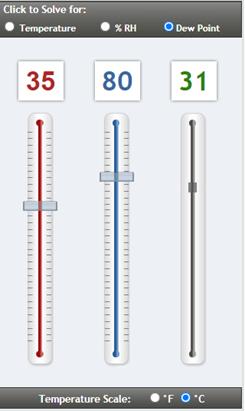

For example: such as above chart the climate of Hanoi zone is more extreme then Ho Chi Minh zone, and on June the climate of Hanoi is the most extreme (temperature is ~35oC, RH~80%/ AH~28 g/m3) thus dew point temperature up to 31oC.

References:

https://www.worlddata.info/

http://www.dpcalc.org/

Handbook: Condensation in buildings of abcb.gov.au

https://www.worlddata.info/

http://www.dpcalc.org/

Handbook: Condensation in buildings of abcb.gov.au

Other articles

- Sigma launched the awareness training program on ISO 9001:2015, 45001:2018 & 14001:2015 (02/03/2023)

- Sigma implements the ISO 45001:2018 management system audit and monitoring program (20/10/2022)

- Why is Ventilation so Important for Buildings? (19/08/2020)

- Effects of harmonics caused by VFD of the HVAC loads in the modern power systems (06/05/2020)

- 5S methodology was implemented at Mikazuki Spa & Hotel Resort Danang project (10/12/2019)

- Advantages of Automatic balance valve in the Chiller system (03/10/2019)

- Some notes in the desgin of the domestic hot water system (19/09/2019)

Partners

_thumbcr_130x97.png)

Address :

Address :  Email :

Email :  Tel : (84-24) 3 9288683 | (84-24) 3 9289235

Tel : (84-24) 3 9288683 | (84-24) 3 9289235 Fax : (84-24) 3 9288667

Fax : (84-24) 3 9288667.png)